Same Job – Different Product

Concrete soakwells and polypropylene soakwells do the same job in similar ways. The purpose of both types of soakwells is diverting excess amounts of storm water and redistributing the water into the water table. Both concrete and polypropylene units allow property owners to avoid damage and remain compliant with ordinances governing water runoff. If you are in the market for a soakwell, neither is a poor choice. However, each type has its own merits and detractions.

Concrete soakwells and polypropylene soakwells do the same job in similar ways. The purpose of both types of soakwells is diverting excess amounts of storm water and redistributing the water into the water table. Both concrete and polypropylene units allow property owners to avoid damage and remain compliant with ordinances governing water runoff. If you are in the market for a soakwell, neither is a poor choice. However, each type has its own merits and detractions.

For years, concrete soakwells were the industry’s gold standard. The strength and load-bearing capability of concrete are relatively unquestioned. A concrete soakwell that is fitted with rebar and wrapped to prevent sand from entering will help to distribute storm water and prevent flooding on your property for decades. Installing a concrete soakwell will provide your home with drainage. However, these are often ideal for industrial and heavy commercial properties. Concrete soakwells are low maintenance and we rarely, if ever, have any complaints from our customers after installing a concrete soakwell.

The stability of a concrete soakwell comes with a price. In many cases a considerably high price to purchase and install a concrete soakwell on your property. Installing a concrete soakwell is no small task; heavy equipment is necessary for digging the hole and transporting the soakwell. After installation, maintaining a concrete soakwell can be somewhat tricky, and repairs require a good amount of manpower.

Drainage professionals began using polypropylene soakwells about two decades ago. Initially, many drainage professionals, as well as customers, were doubtful about the strength and durability of this new kind of soakwell. As time passed, the doubters were impressed as the polypropylene soakwells held up and efficiently served their purpose.

Polypropylene Soakwells – Strong & Cost Effective

Polypropylene Soakwells – Strong & Cost Effective

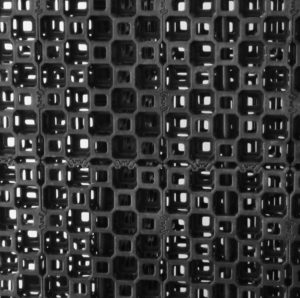

Choosing to install a polypropylene soakwell is a smart way to save money without compromising quality. This sort of soakwell comes in individual blocks which attach to each other. The separate soakwell blocks allow us to customise your drainage unit. By customising, you will have the necessary size of soakwell connected in the most efficient way possible. A custom design also makes installation faster and less invasive than the installing a concrete soakwell. In order to install a large concrete soakwell, much digging is necessary. Maintaining or repairing a polypropylene soakwell is not hard because once installed, these units are more accessible than concrete.

Polypropylene soakwells are exceptionally strong and durable. The strength of these soakwells surprises some of our customers because the units are lightweight and somewhat rigid. The polypropylene material is not harmful to the environment, it resists corrosives, and it is treated to enhance hardiness. A polypropylene soakwell can bear up to 32 tons of weight, making them ideal for most residential and commercial properties.

Choosing the type of soakwell you want on your property can feel like a big decision, but both the concrete soakwells and the polypropylene soakwells will give your property the necessary drainage. Contact us today 0400 665 312 get the job done right with the Soakwell Experts.